FREE Shipping at $100 *UPS Ground in the contiguous U.S.A.

Fastedge Build Page |

||

Average Ratings:

"Total game changer"

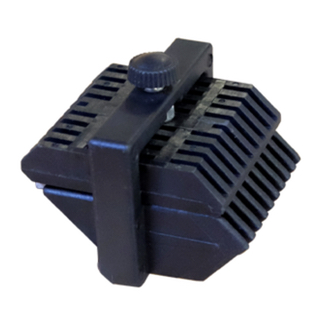

Review: I cannot tell you how fast you can edge band using this PSA banding. I just finished a project and used 500' of the PVC banding and I can't imagine if I had to use an iron to secure the edge banding, it would have taken 3 times longer. The adhesive is extremely strong and very difficult to remove but not impossible. If you want the project to go even faster, buy the roller and the carbide flush timer, both are very good and save so much time.

"Fairly good product"

Review: I decided to try this edge banding for a total kitchen remodel during which I built all the frameless cabinets. After ripping the plywood for the boxes, I sanded the edges lightly, then wiped them clean, making sure there was no foreign material on them. After applying the Fast Edge, I rolled it with a high-pressure laminate roller, then trimmed it using the Fastcap trimmer. I would then roll again making sure to put good pressure on the edges. Most of the edges stayed tight as desired, but several of them loosened on the edges, and some of them even came completely loose. I was forced to use an iron to soften the glue and then re-rolled them with the laminate roller. This technique, so far, seems to correct the problem. Another problem I have experienced is "cupping", where the edges come loose but the center stays flat. Again, an iron fixed this issue. Another reviewer mentioned "fracturing" which is something I also experienced, but not just at the end of the roll. I lost several feet of material due to this. The upside to this product is that it is easy to use, although you need to be sure your environment is clean, including your fingers. It also paints well. It trims easily, but make sure to be careful and trim with the grain. Overall I believe this is a fairly good product.

"Absolutely Amazing"

Review: This edge banding is next level Ive never had such a painless and almost satisfying interaction with Iron on edge banding this stuff was so easy to apply and the selection is like no other.

Response: Thanks, Triston!

"pretty good stuff."

Review: for edge banding veneered plywood products i've used ripped solid wood (3/16" rips of 3/4" red oak, birch or maple), iron-on products, and fastedge. ripping solid wood is the most expensive but gives the best end result, iron-on products are good, easy to use and locally available and i've had satisfactory results, fastedge also gives good results.

fastedge is super, gives a good result, but can be messy (adhesive difficult to sand down; debris sticks to everything) and when you get to the end of the roll of the natural wood products you find fracturing (due to tight radius of material at the end of the roll) which means more finish time.

after using all these techniques to cover the edges of veneered plywood for my projects, i now stick with either the iron-on product (cheaper, just as reliable, and locally available at the 'big box' stores), or fastedge (more expensive and messier).

"How to Plywood Edging Using FastEdge"

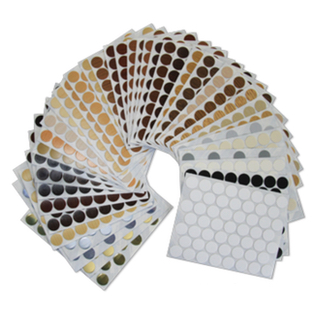

Review: This is a fast and simple system that allows you to band (edge) plywood in minutes instead of hours. Much easier than ripping down wood and gluing and pinning to the edge. FastCap offers this edging in real wood (both finished and unfinished) and laminate including colors, wood grain and metallic.

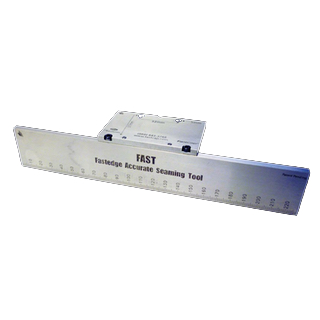

Read more reviews > How thick are Fastedge and Fastcaps?Our material thicknesses including the adhesive are as follows: PVC= .025" Unfinished Real Wood= .035" Prefinished Real Wood= .028". I am purchasing Fastedge for the first time. Is it better to buy a width that is bigger than the edge I am applying it to or should I buy the exact width I need?It is best to buy a width a little wider than what you need so it is quick and easy to apply to the edge and trim it without having to stress about lying it down exactly right. We also strongly recommend watching ALL of our Fastedge videos (see the video tab). They are just a few minutes long and by the time you're done watching them, you'll be a Fastedge pro in no time! I need to match a laminate for my project. Can you help me find a match to your Fastcaps and Fastedge?We have 70 stock colors in our Fastcaps and Fastedge and we can also match custom colors for you. If you know the laminate or melamine brand that will make matching much easier. Call us at 1-888-443-3748 with the color information and we can see what we have available. We also sell a Sampler Pack, PVC Sampler Pack and a PVC Color Sample Chain. I just applied Fastedge to my project and there is adhesive oozing from the sides. How do I clean this up?You must be very careful when you are trying to clean excess adhesive off when using any kind of chemical because you run the risk of causing the Fastedge adhesive to fail and start curling up on the sides. Try using a razor blade to carefully scrape the excess adhesive. I need to match a laminate for my project. Can you help me find a match to your Fastcaps and Fastedge?We have 70 stock colors in our Fastcaps and Fastedge and we can also match custom colors for you. If you know the laminate or melamine brand that will make matching much easier. Call us at 1-888-443-3748 with the color information and we can see what we have available. We also sell a Sampler Pack, PVC Sampler Pack and a PVC Color Sample Chain. Does Fastedge work on exposed MDF edge and ABS edging?Fastedge will work on exposed MDF, but there are additional steps needed to prep the surface before application. You need to apply a binder coat of 50% contact cement and 50% acetone with a roller and then let this binder coat stand for 10 minutes or until tacky before applying the Fastedge. Fastedge does not work well with ABS panels. We do not recommend using our product for those panels. The adhesive will stick for a short time but will end up peeling eventually as these materials are not porous so there is nothing for the adhesive to bind to. Can you use Fastedge for 1/8” solid edges?Yes, of course. You will have to order it wider than 1/8” – we don’t sell it in less than ¼” (its easier to apply wider than the material and trim anyway). So make sure you pick up a Quad Trimmer as well! If I'm making radiused edge plywood, as in a kitchen stool, can I use Fastedge as one continuous piece? If so what is the smallest radius I can wrap it around?Yes, you can. Should be able to work on as small as about 3-5” radius. Using a De-Curl backward to actually create memory before applying it, to get it to naturally sit in the radius would be a good idea! How do you recommend flattening Fastedge? |

.png)

4.5

4.5

.jpg)